Electrocoagulation System

Electrocoagulation is a simple and effective method of removing various heavy metals, metalloids, organic substances, ammonia, nitrates, phosphates, etc. from contaminated water.

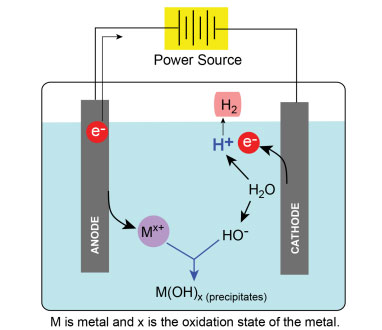

The process is performed by applying an electric current across metal electrodes that are submerged in water. When the electricity passes through the electrodes, metal ions are released from the sacrificial anode and combine with hydroxide ions produced at the cathode.

This results in the formation of polymeric metal hydroxides, which are excellent coagulants. These coagulants trap and remove contaminants present in the water. Basic concept of electrocoagulation is schematically presented in the illustration.

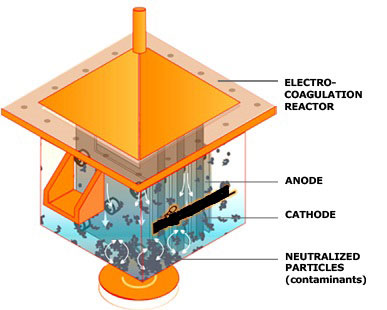

Electrocoagulation is a specialized coagulation technology utilizing electrical energy. This electrolysis process utilizes methods that precipitate out large quantities of contaminants in one operation. This Neya Water Solutions electrocoagulation wastewater treatment technology is the distinct economical and environmental choice for industrial, commercial, and domestic wastewater treatment. This system solution also has applications in municipal water treatment and storm water reuse.

Neya Water Solutions is devoted to providing advanced, innovative modular electrocoagulation water treatment solutions specifically designed for drinking water, process water, gray water recycling, industrial and municipal waste water applications.

Using this advanced technology, we are able to assist our clients in removing or significantly reducing:

Neya Water Solutions specialized electrocoagulation wastewater treatment and potable water treatment solutions are designed, engineered, built, and integrated into an optimized treatment process including pre and post treatment to solve our clients specific needs.

Advantages of NEYA Electrolytic Coagulation:

In working with our clients and local partners worldwide, NEYA designs and builds complete custom built integrated electrocoagulation wastewater treatment and water treatment solutions to meet the most challenging water quality issues that our clients face.

These integrated solutions have specific applications in the following industries: